Kijkje achter de gordijnen tijdens de bouw van een LFA

- mei 12th. 2011

- Toegevoegd inLexus LF-A

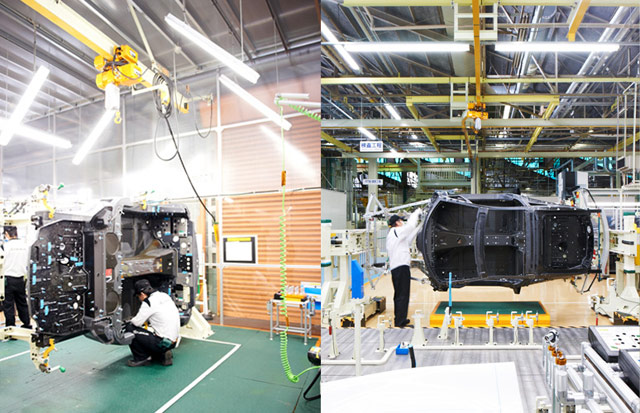

Lexus Magazine heeft een fotoreportage samengesteld wat het proces van het bouwen van een LFA, in het fabriek in Motemachi, laat zien. Hier zijn een aantal van de 21 slides met bijbehorende beschrijving (engels):

Enter either of the two buildings at the Motomachi plant, where the LFA is made, and you’ll find your senses quickly overloaded. Despite its hangar-like size, the place is more premium body shop than factory: paint scents hang in the air, while heaters and air extractors hum steadily, punctuated by the whirs and bursts of torque wrenches. And then there’s the car. It can be seen in all stages of assembly here, from sheets of carbon fabric to the finished article—a captivating sight.

When the body shell components are complete, the surfaces are slightly roughened with a treatment of water and abrasives, which makes them ready for bonding. Then, for some parts, glue is applied by robot (one of the few around); after that, specialists apply glue to the remaining body shell parts and conduct initial inspections.

The last step inside the facility: post-assembly inspections, an elaborate affair conducted in a closed off room with a lighting arrangement designed specifically for the LFA. Here, the specialists check for secure fitting and perfect alignment of each car’s exterior components. If there’s 1/100th of a millimeter difference in, say, a panel gap from one side to the other, it’s adjusted to perfection.

After passing inspections, each LFA is turned over to test driver Nobuaki Amano, who has, without a doubt, one of the coolest jobs in the world: conduct LFA performance checks at the LFA Works’ test track. With each vehicle, he focuses on seven key areas at speeds up to 125 mph: controllability, driving feel, sound, brake performance, power, noise and vibration, and the function of parts.

Zoals al geschreven, dit is slechts een deel van de slides. Voor meer slides kunt u hier terecht.

Bron[LexusEnthusiast][Lexus Magazine]

mlcoolj.